This unit to study the heat transfer rate on composite structures made up of different material. This unit consists of Heater, Temperature indicator & Sensors, Composite slab with Transparent cover etc.,.

web.jpg)

- Composite slab assembly with transparent front view

- Slab material : Wood, Steel, Aspestos (Size : 200 mm)

- Electric heater to heat the slab temperature

- Variable voltage source for heater

- Metal tube with lagging material are filled in tube

- Lagging material are rolled on heater

- Variable voltage source to supply the heater input

- Heater (500 watts) with indicator provided

- Concentric copper sphere, inner sphere heated by a concealed electricheater.

- Specimen plates provided

- Digital temperature indicators with multichannel switch

- Electric heater to heat the specimen.

- Specimen bar provided

- Digital temperature indicators with multichannel switch

- Temperature sensor to sense the various place.

- Fin is fixed on the heater

- Blower with mini Duct provided.

- Temperature sensor

- Multichannel digital temperature indicator

- Variable voltage source for heater supply

- Spring heater mounted on copper tube.

- Blower to supply air through the tube.

- Orifice with U tube manometer provided.

- Variable voltage source for heater supply

- Rod heater fixed on pipe

- Heater setup with transparent cover

- Thermocouple as a temperature sensor

- Variable voltage source for heater supply

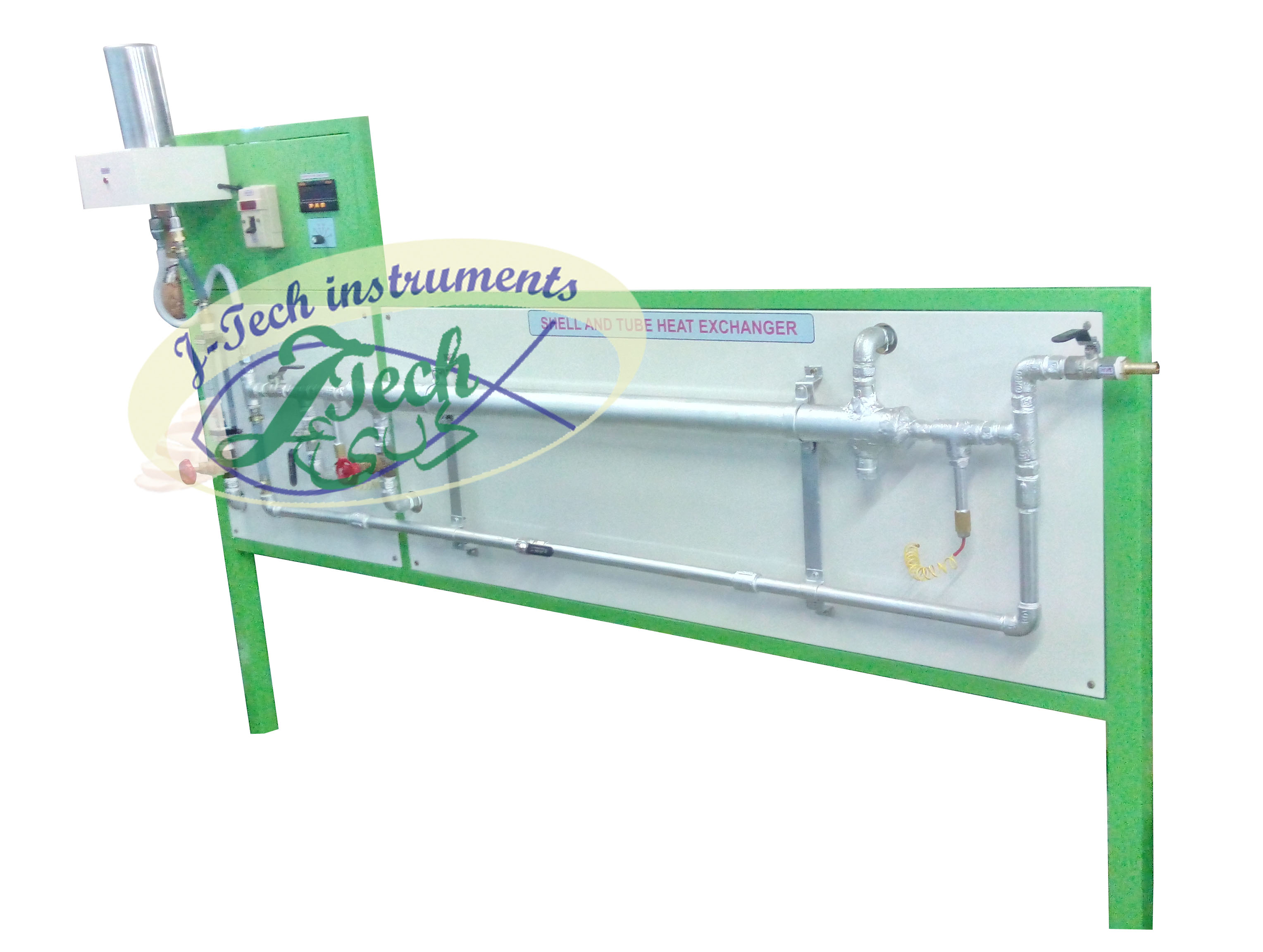

This unit consist of heat exchanger, instant water heater, RTD / Thermocouple sensors with indicator, heater power controller etc. to study the performance of parallel and counter flow heat exchanger.

web.jpg)

- Aluminum Disc to find the emissivity.

- Electric disc heater

- Thermocouple sensors to sense the variable place

- Multichannel temperature indicator to indicate the all temperature.

- Industrial water heater

- copper disc is fixed in a handle

- Thermocouple used to measure the temperature at different point.

- Multi-channel temperature indicator

- All components are fixed in MS panel with powder coated frame.

This unit consist of compressor, condenser, evaporator, expansion valve, temperature sensor, pressure gauge etc., to study the effect of heat transfer co- efficient

- Two stage two cylinder air compressor

- Air tank with suitable panel

- Temperature sensor with multichannel indicator

- Energy meter, Stop watch, Pressure Gauge, Starter, Pressure Relief valve provided

This unit used to demonstrate and performance of cooling tower. It consist of Cooling tower, Heater, Blower, Nozzle, Rotameter and Temperature Sensors.

This unit consists of compressor, condenser, duct, expansion valve, temperature sensor, pressure gauge etc., to study the effect of heat transfer co- efficient